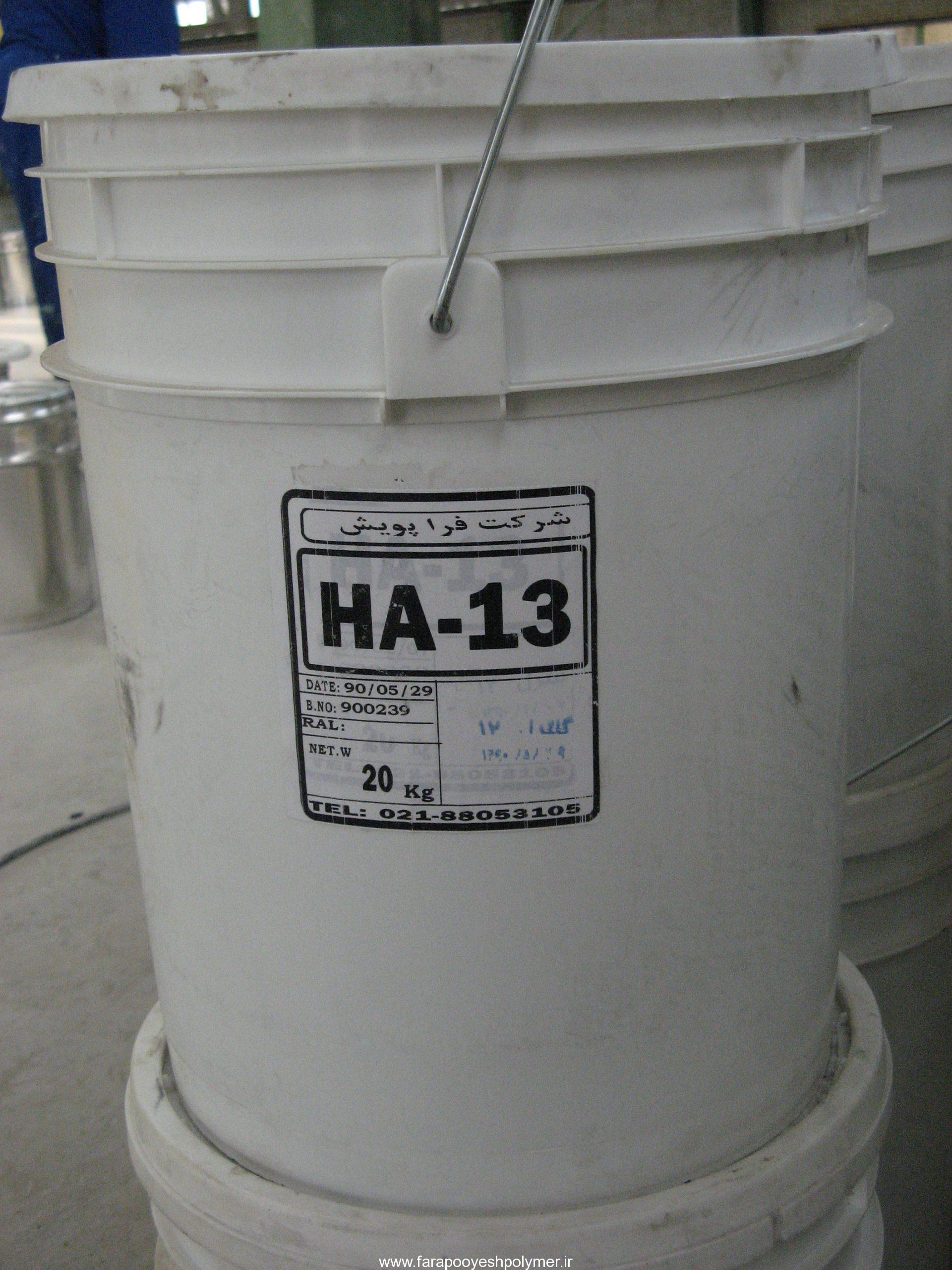

انواع هاردنر اپوکسی

هاردنرهای اپوکسی

هاردنرهای مورد مصرف در صنعت کفپوش عمدتا به دو گروه عمده اصلی زیر تقسیم میشوند

هاردنرهای پلی آمید : این گروه از هاردنرها عمدتا در رنگهای اپوکسی و پرایمر کاربرد داشته و بدلایل خصوصیات مناسب زیر استفاده گسترده ای دارند : انعطاف پذیرند مقاومت بالا نسبت به ضربه و مواد شیمیایی دارند و بدلیل چسبندگی بالا به بتن و مقتاومت مناسب به رطوبت در صنعت کفپوش عمدتا بعنوان هاردنر پرایمر مورد استفاده قرار میگیرد .

هاردنرهای پلی آمین

IHهاردنر پلی آمین این هاردنرها بسیار در صنعت و بخصوص صنعت کفپوش کاربرد داشته و برای روکش و لایه های کفپوش استفاده میشود این هاردنر بامقاومت شیمیایی نسبتا خوب معمولا در لایه ها و روکش استفاده میشودو رزین پس از خشک شدن بسیار سخت گردیده ودر دمای اتاق خشک میگردد

محصولات مرتبط

Floor cleaners

One of the main problems of polymer flooring including epoxy flooring, polyurethane flooring, as well as PVC roll flooring in all companies is that they are difficult to clean after getting dirty compared to ceramics and glossy stones, so to solve this problem many companies Multi-color designs are used in the production of these floors, and the use of light-colored monochromatic floors in crowded places will be one of the challenges of flooring after a while that even quality quality cleaners can not solve this problem. It is efficient and removes all dirt and grime on the floor in a few seconds without any color change.

The way to use this detergent is that due to the dirt, the floor of pure detergent is mixed with a suitable percentage of water and poured on the floor and spread with T, then it is rubbed on the surface several times with a rough broom and after finishing the whole surface is washed with water. , Clean and dirt is removed and finally delivered as a surface like the first day

Epoxy resin

Resins used in the flooring industry are mainly divided into the following two main groups

Resins used in floor primers that are used with polyamide hardeners

Resins used in veneers and floor coverings, which are mainly used with polyamine hardeners, and the most popular is 828 resin.

Hexion Company, which is very famous due to its low viscosity and excellent adhesion, and chemical resistance.

It is very good and in dry weather it has little sensitivity to temperature changes and its mechanical properties do not change over time.

Resins that can be provided in translucent floors with 828 resin or its quality equivalent.

پودر کربنات کلیسیم

کربنات کلسیم یک ماده پرکاربرد و فراوان در پوسته زمین است . کربنات کلسیم نوعی سنگ رسوبی است که در طی میلیونها سال تشکیل شده است . کربنات کلسیم در معادن به شکل کلسیت ، آراگونیت ، ،سنگ مرمر، سنگ آهک یافت میشود .

این ماده نقطه ذوب بالایی حدود 1339 درجه سانتیگراد داشته و غیر قابل اشتعال بوده و غیر سمی است .

این ماده معدنی و پر کاربرد ارزان بوده و فیلر مناسبی در بسیاری از کاربردها در صنعت رنگ میباشد .